Our Land Based Advantage

Our products have been widely used in the land based process industry since the nineteenth century

Leveraging our historic achievements and expertise in design and manufacture of heat transfer products for land-based applications, we continue to develop and expand our product range for the ever-evolving process industry.

We cater to the international land based oil/gas, power and energy sectors and have supplied

equipment to power stations, petrochemical facilities, mines and metal production facilities, pharmaceutical and refining industries and to most mid stream industrial engineering sectors such as automotive, paint, food/beverage, wood pulp and paper manufacturing industries.

Leveraging our historic achievements and expertise in design and manufacture of heat transfer products, we continue to develop and expand our product range for the ever-evolving process industry.

We cater to the international land based oil/gas, power and energy sectors and have supplied equipment to power stations, petrochemical facilities, mines and metal production facilities, pharmaceutical and refining industries and to most mid stream industrial engineering sectors such as automotive, paint, food/beverage, wood pulp and paper manufacturing industries.

Our goal is to provide economical solutions for power generation with increased plant efficiency, reduce harmful environmental emissions whilst saving energy.

INDUSTRIAL BOILERS

THREE PASS WET BACK SMOKE TUBE BOILERS

STEAMPACKET M

OIL / GAS OR DUAL FUEL FIRED PACKAGE BOILER

A Steampacket Packaged Boiler is a smoke tube wet back construction without refractory at the rear and lends itself for easy conversion to various oil and gas fuels with heat release rate for quick and uniform combustion.

The fully automatic controls with auto change over switch for emergency manual control give flexibility to the operation. Maintenance is easy with end to end doors for fast cleaning and minimum downtime.

The M Series are fitted with either pressure jet spill return Monoblock burners or gas firing burners or dual fuel firing types. The steam output range is from 1 TPH to 5 TPH on F&A 100 Deg C conditions with all essential fittings assembled on a base for minimal space requirement and simple installation.

STEAMPACKET D

OIL / GAS OR DUAL FIRED PACKAGE BOILER

This Steampacket D series comes with Dual Block Burners suitable for oil or gas or dual fuel firing. Like all the Steampacket series this is also of three pass, wet back, fully packaged type of fusion welded construction. The range is from 6 TPH to 16 TPH.

These liberally rated boilers achieve maximum output whilst retaining compactness, to minimise floor space. The main features include large furnace to avoid flame impingement, large water and steam space for meet fluctuating loads without fall in boiler operating pressure and dryness fractions to the order of 0.995.

Adequate access to both steam and water spaces are provided together with front and rear access doors for ease of maintenance.

Standard equipment includes pressure jet or rotary cup combustion equipment, steam and water mountings, feed water level controls, feed pump, integral wiring, insulation and cladding.

MAXECON T

OIL / GAS OR DUAL FUEL FIRED PACKAGE BOILER

This Maxecon T with a steam output range up to 40 TPH is a twin furnace boiler used in industrial steam or hot water applications. It is a very high-quality boiler with a track record of highly efficient performance and reliability. When fitted with special control panels, single furnace firing is possible for indefinite periods. This ensures a lower turn down ratio and also permits maintenance work to be carried out on each burner in turn, whilst boiler output is maintained at up to 50% of normal rated output on the other furnace.

Can be supplied with super heaters to suit specific applications. Cylindrical, fully corrugated furnaces of welded construction are attached to each reversal chamber and the boiler front plate by welding.

Tubes are combination of plain and stay tubes are welded in. Plain tubes are expanded and seal welded in the reversal chambers. Integral superheaters can be accommodated with in this boiler to attain maximum outlet temperature of 300 Deg C.

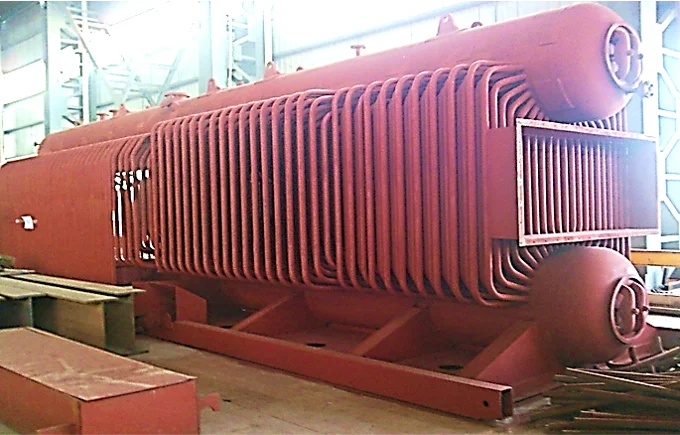

WATER TUBE BOILERS

D TYPE BOILER

The D type water tube boiler is designed to have a large steam drum at the top, vertically connected to a smaller water drum at the bottom, via multiple steam-generating tubes which carry feed water. These provide the primary heat transfer surfaces for the production of steam. This arrangement is further surrounded by walls made up of larger water-filled tubes, which make up the furnace.

The D Type water tube boiler design facilitates good feedwater circulation, faster steam generation and lower project cycle time as well as costs.

The simplicity of the two drum type shop assembled configuration uses large diameter tubes to minimise internal fouling and easy maintenance.

The large furnace along with integral superheaters can be provided for higher steam temperature requirement and high pressure firing of oil, gas or oil/gas combination burners. The membrane type water wall gives gas tight construction to the boiler.

ESD BOILER

The ESD boiler (External Superheater Design) is specifically meant for power generation applications, and developed for long life, high availability / reliability and consistent good quality of super-heated steam. Output capacities range from 50 TPH to 300 TPH.

The ESD Boiler is a compact boiler (small plan area) with a reputation for reliable production of Superheated Steam, with minimal down time, resulting in extended periods of effective operation between repairs. It is designed for a long-life superheater. The main cause of failure in all superheaters is creep, and typical life on some boilers can be as little as 5 years; however, for an ESD boiler which is correctly operated, the superheater life can exceed 10 years, because it is protected from prolonged periods at higher temperatures.

The secondary and primary superheaters are hidden from direct thermal radiation from the flames by a screen wall. Also, the secondary superheater is designed for parallel flow, which further protects it from high temperatures.

Additionally, on an ESD boiler, the flow arrangement for the superheated steam means that the tubes exposed to the hottest gas from the furnace are kept cool by passing attemperated steam to these tubes, thus protecting them from overheating.

Hence, instead of higher-grade alloys that are more difficult to fabricate and repair, the ESD boilers can use low grade Chrome Molybdenum tubes for both primary and secondary superheaters.

The ESD boiler has a high thermal efficiency of upto 95%, which results in lower fuel costs. Its reliable, proven boiler design requires less commissioning time, has a well-established operational safety record, and offers ease of inspection and maintenance.

RENEWABLE ENERGY

SOLID FUEL BOILERS

We apply cutting edge technology to conceptualise and engineer solutions to harness energy from naturally replenishable resources such as biomass and other agricultural wastes. We have both fluidised bed and grate combustion in this range for efficient utilisation of biomass fuels.

The fluidised bed combustion has the advantage of higher thermal efficiencies, reduced heating surface area and furnace volume, resulting in compact foot prints, suitability for low grade fuels and high ash fuels, easy ash removal, less fouling and tube corrosions.

The grate combustion brings sturdiness and flexibility to accept difficult fuel characteristics and composition. This continuously conveys the fuel through the combustion chamber and the fuel feeding can be automatically controlled. With adequate residence time it provides optimum burning to the fuel and surface exposure to the flame over the entire grate area.

CONSTRUCTION / SITE SERVICES

We have extensive experience and possess an excellent track record of working with international operators to execute large scale projects for the Energy industry.

We strongly believe in and actively pursue global network company partnerships, associations and cooperation, adopting a 21st century approach towards project work. Through such associations we can execute large scale regional projects with success and within defined time frames and budgets.

- Proven and successful engineering capabilities (full project cycle)

- Engineering and technical supply (all disciplines)

- Engineering, procurement, construction (EPC)

- Project management completion (PMC) and interface management

- Health, safety, environment, quality (HSEQ) & risk management

- Factory acceptence testing (FAT’s) and site acceptence testing (SAT’s)

- Mechanical completion (MC) management

- Commissioning (all disciplines)

- Training services and vendor bespoke training programs