Our Marine Based Advantage

We have been at the forefront of marine thermodynamic design technology for over fifty years

We offer a wide range of marine based solutions, from design services to bespoke built-to-order marine applications. With a wealth of experience across a broad spectrum of naval and merchant vessels including fixed and floating offshore facilities, we design and supply quality products

with competitive pricing.

Accredited to ISO 9001 / EN 29000, pressure parts are designed to comply with relevant marine classification society or in accordance with ASME Code.

We offer a wide range of marine based solutions, from design services to bespoke built-to-order marine applications. With a wealth of experience across a broad spectrum of naval and merchant vessels including fixed and floating offshore facilities, we design and supply quality products with competitive pricing. Accredited to ISO 9001 / EN 29000, pressure parts are designed in accordance with ASME Code “S” and “U” stamps, complying to all major classification society specifications.

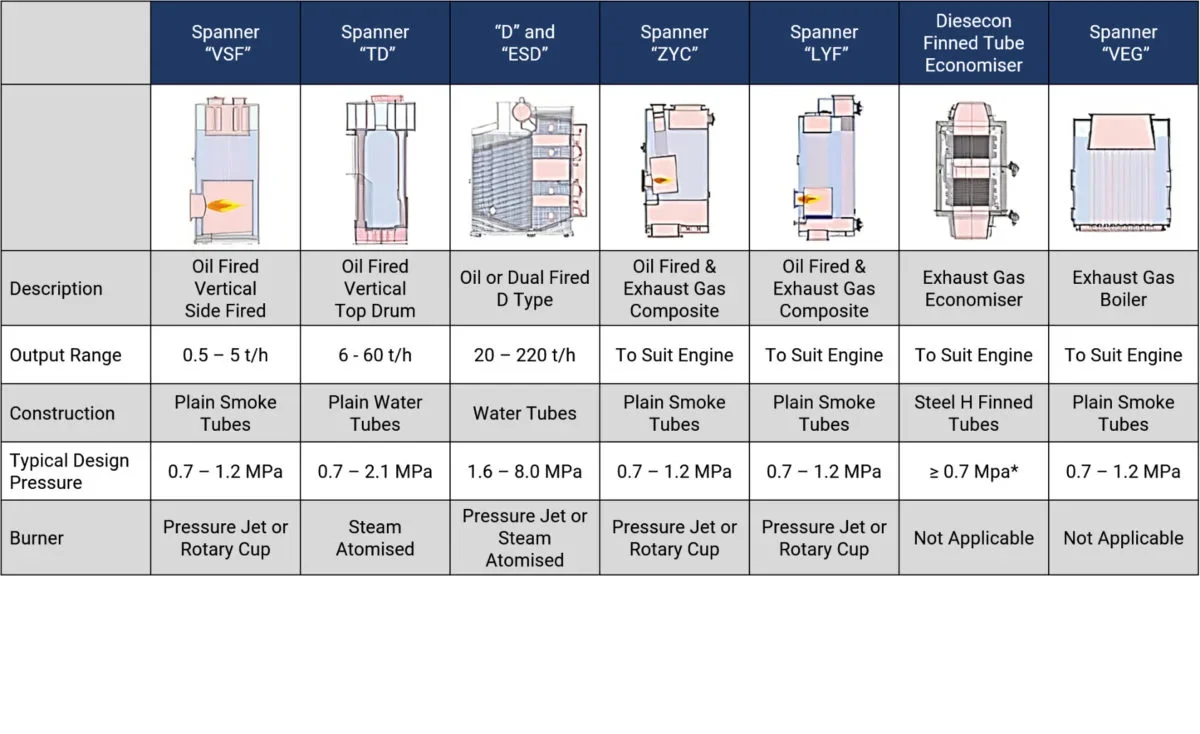

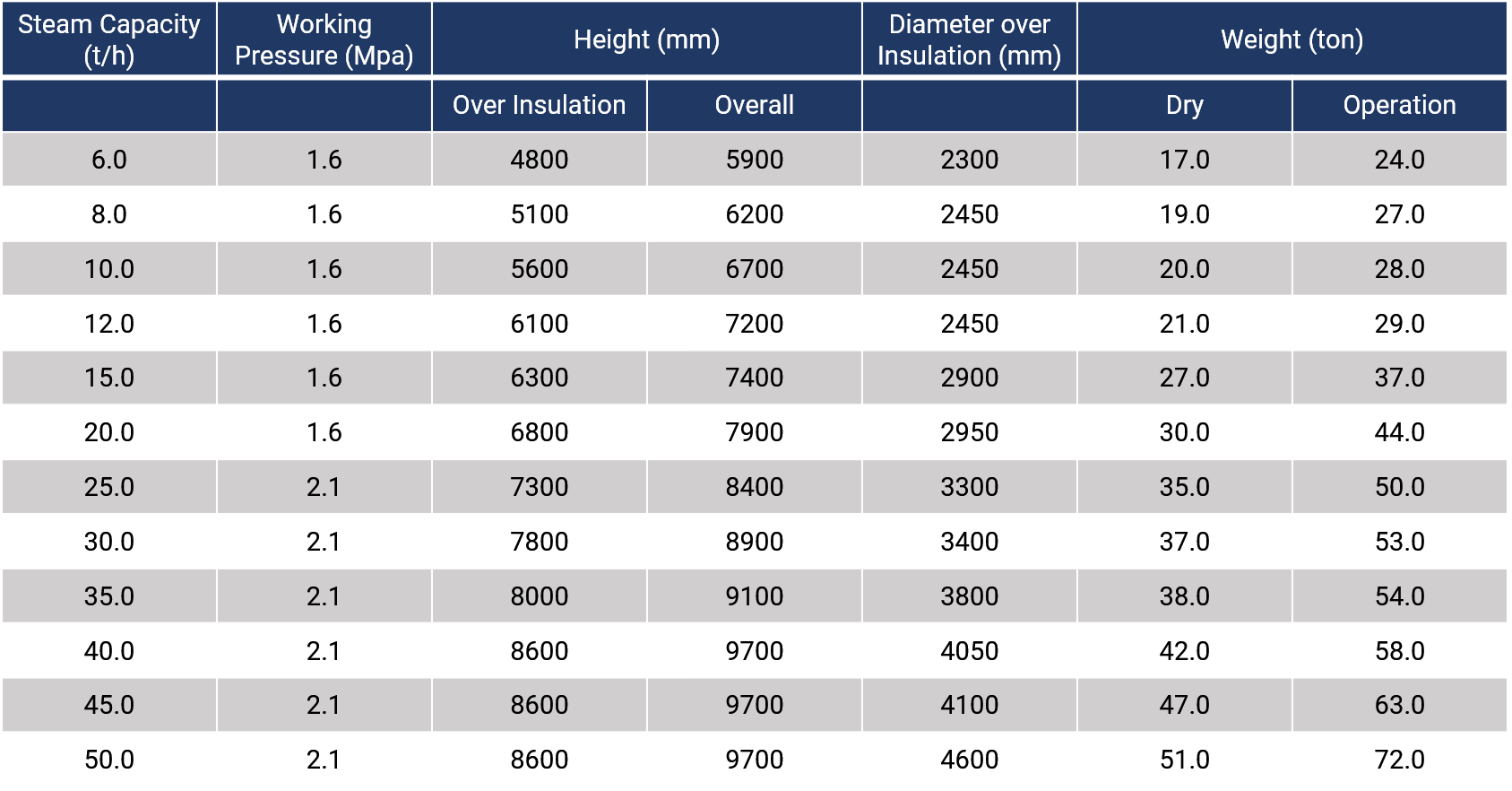

OUR RANGE OF MARINE BOILERS

We are an established manufacturer of Marine Boilers and economisers, offering a comprehensive range of services, from boiler design, fabrication and supply to service repair and survey services on a global basis, from our facilities established in Singapore.

We offer all kinds of marine boilers and boiler spare parts for FPSOs, LNGs, oil tankers, container ships, bulk carriers, engineering ships, etc. We also offer client support and repair services globally.

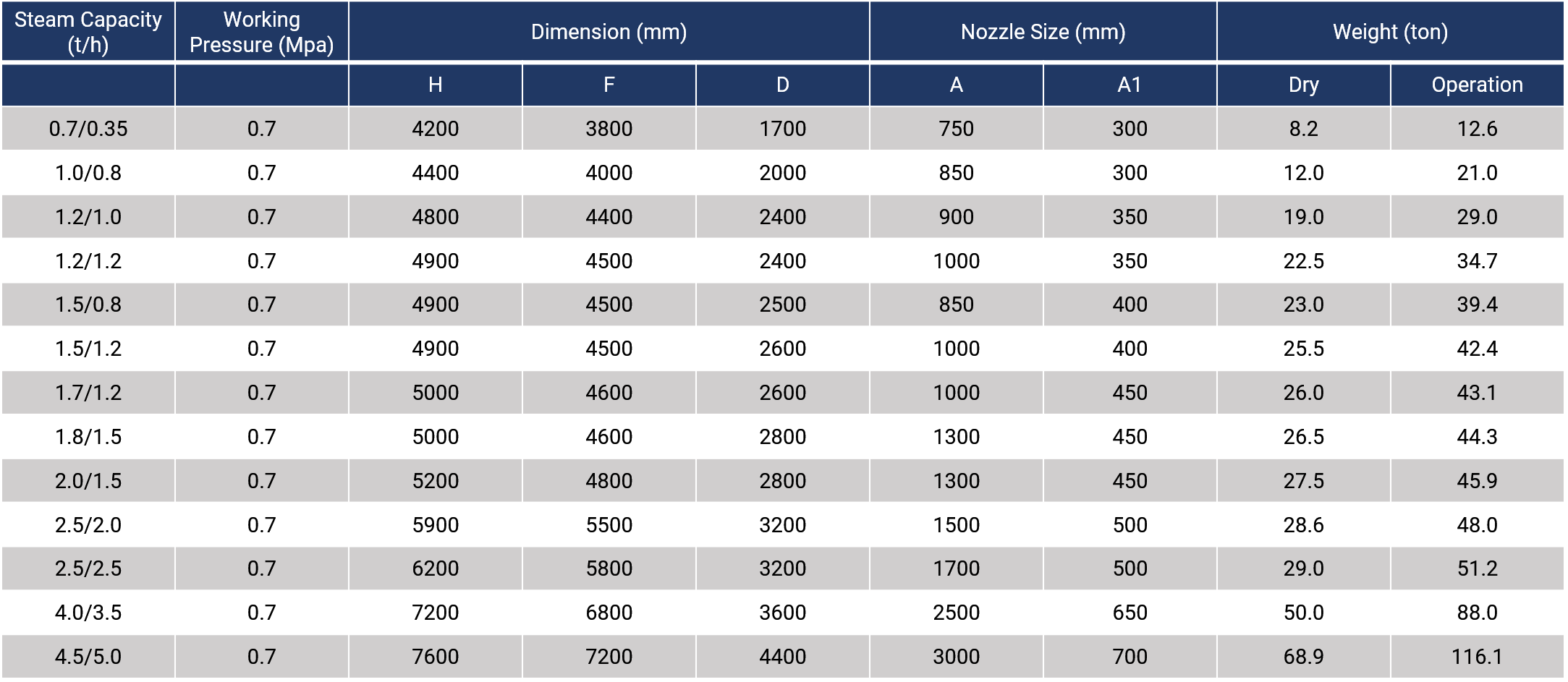

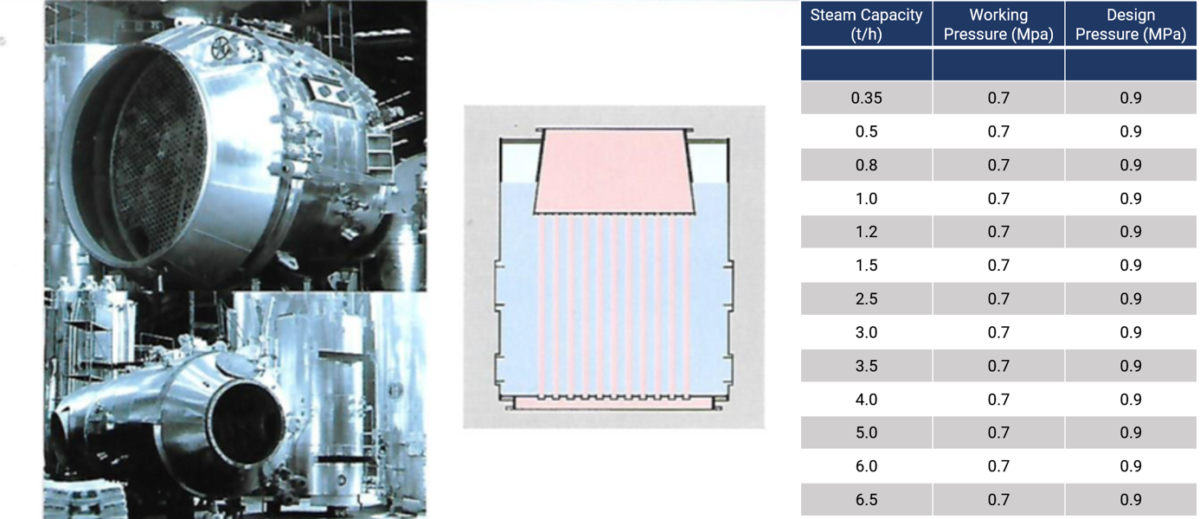

*Design Pressure can be changed according to the ship’s requirements

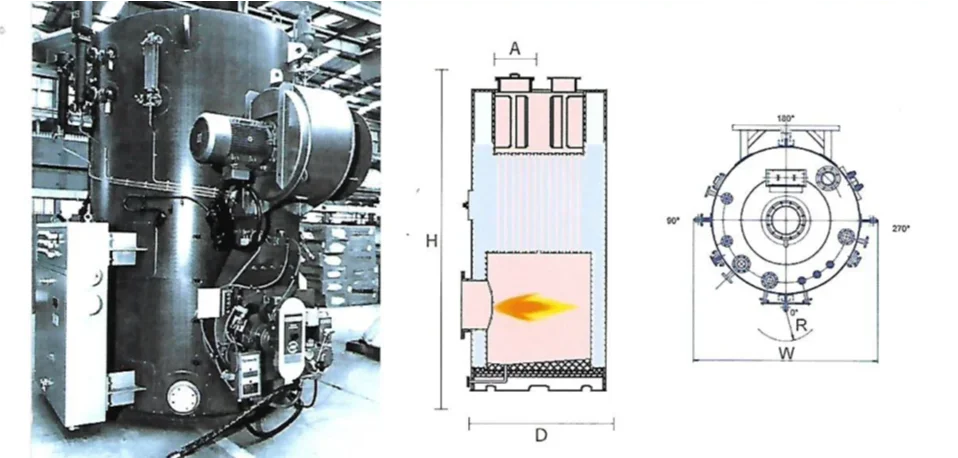

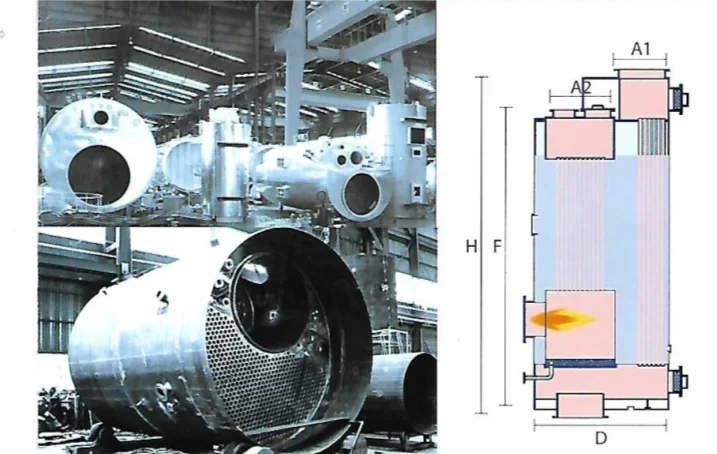

SPANNER VSF

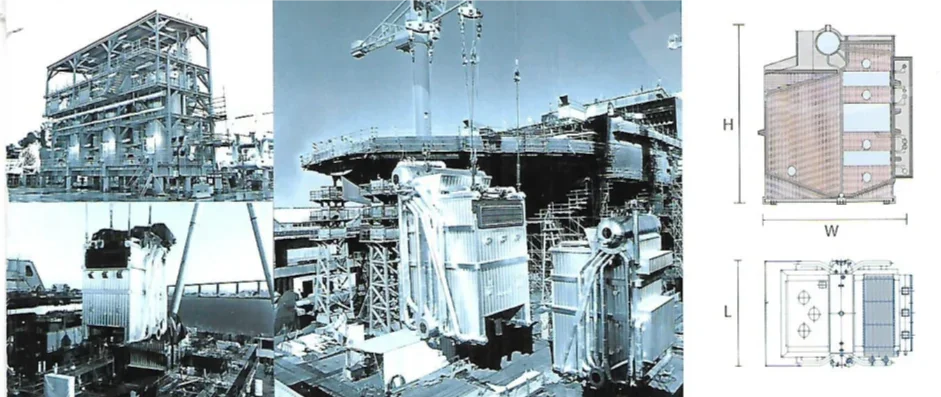

SPANNER TD

For TD Boilers with outputs of larger capacity, please contact us with your specific requirements

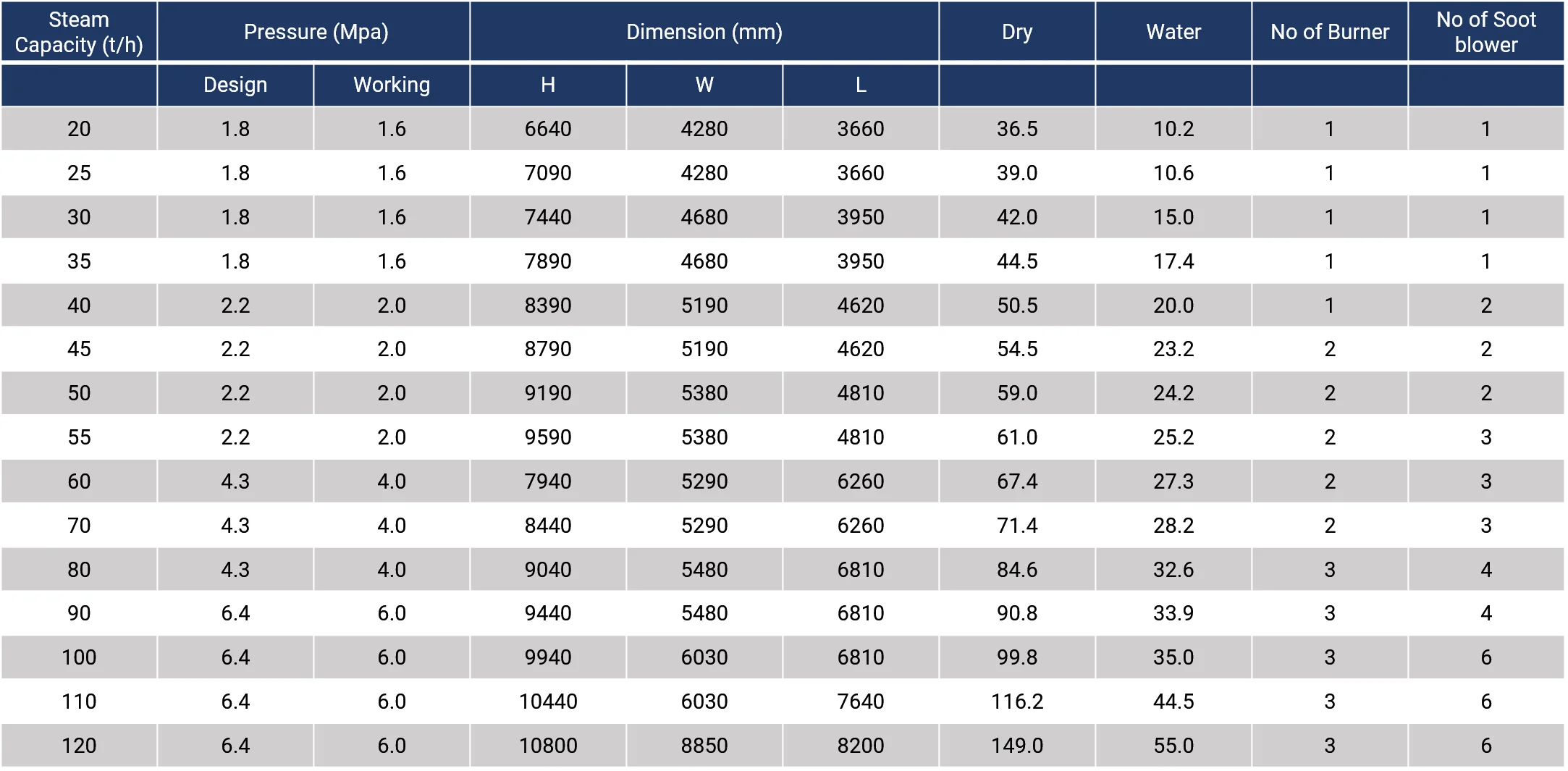

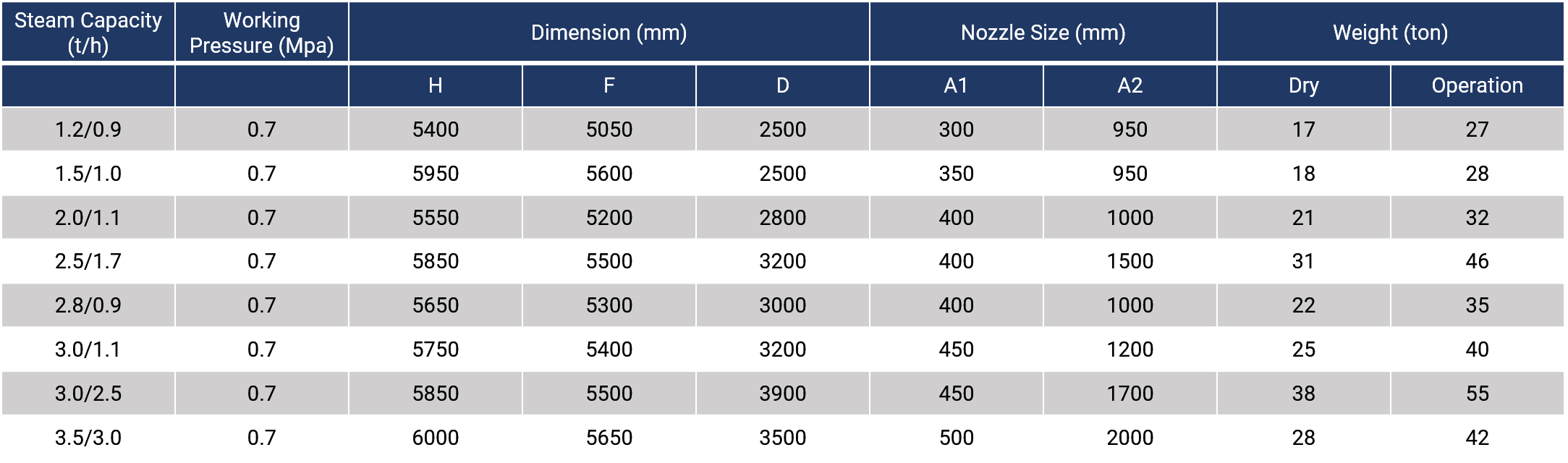

SPANNER D & ESD

For ESD Boilers with outputs of larger capacity, please contact us with your specific requirements

SPANNER ZYC

Above dimensions are typical – final dimensions depend on exhaust gas flow and steam output required from waste heat.

SPANNER LYF

Above dimensions are typical – final dimensions depend on exhaust gas flow and steam output required from waste heat.

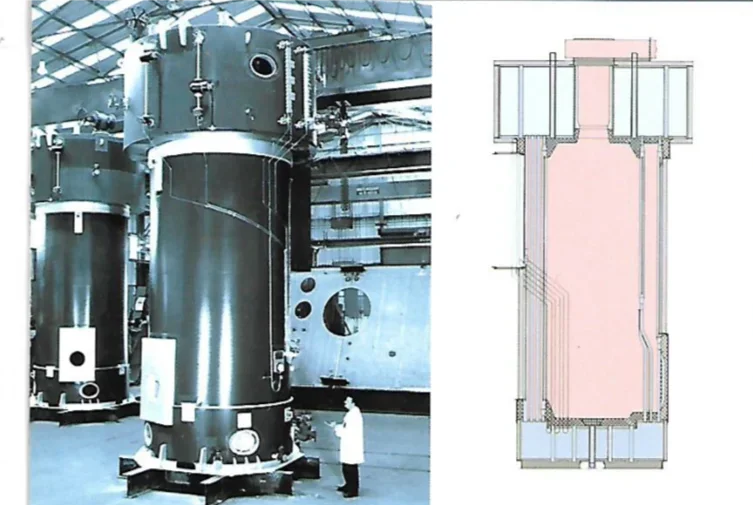

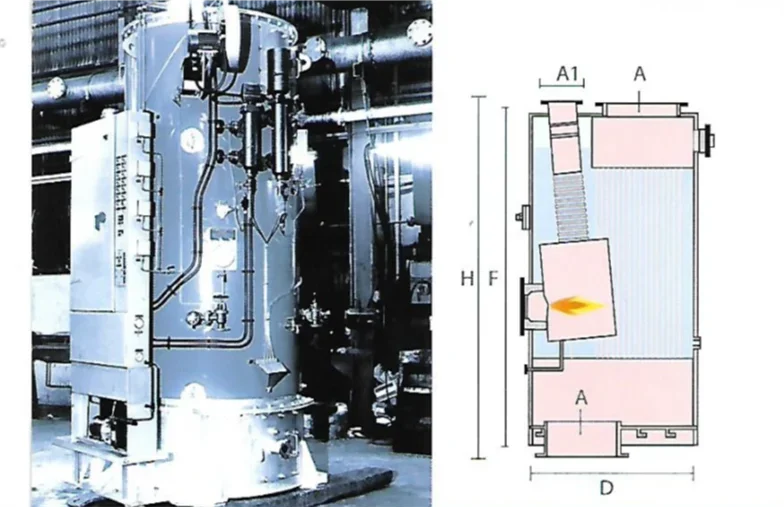

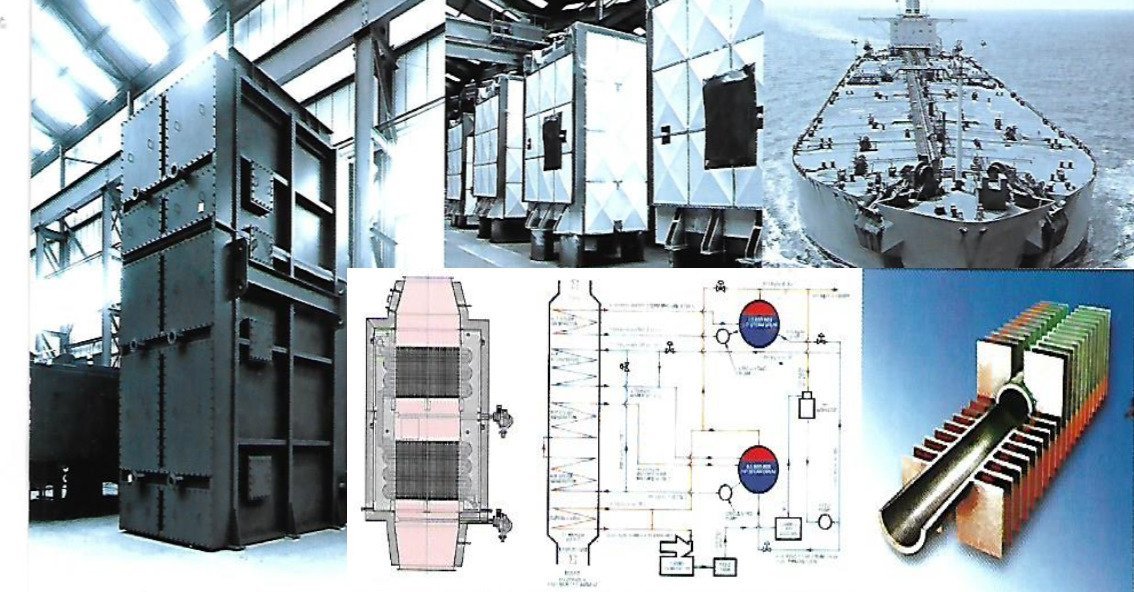

SPANNER DIESECON

Power Generation

The Greens Group Diesecon Boiler is designed to produce superheated steam and saturated steam as required from heat generated from exhaust gases. Wherever there is sufficient heat generated by exhaust gases, superheated steam can be produced and utilized in a Turbo-Alternator to generate electricity. This generally results in the reduction of number of Diesel Generators fitted on board, which in turn reduces overall operational expenses for the vessel.

The Greens Group can also help to determine feasibility of specific projects by providing an assessment of the amount of power that could be generated. Care is always taken in the design to protect the boiler and associated ducting from possible external corrosion as a result of combustion of fuel containing sulphur.

To maximise both heat recovery and power generation, both single pressure and two pressure boiler systems can be offered. The boiler can also be designed to work in conjunction with any other heat recovery systems applied to the engine charge air and jacket water cooler.

Salient Features

- Steel ‘H’ extended surface tubes are used to transfer the heat from gas to the water/steam.

- The Steel H Diesecon has compact overall dimensions, with low dry weight and low water weight.

- Parallel fins allow high gas velocity with low draught loss, ensuring effective cleaning of heating transfer surface.

- Fins are electric fusion welded to tubes. Multi point contact ensures continuous high strength weld with optimum heat transfer rates and resultant low fin tip temperatures

- Robust fins (up to 3mm thick) and tubes (3.5 – 4mm wall thickness) are designed to ensure effective performance and extended service life.

- Tubes and fins are standard carbon steel. For special applications, corrosion resistant Corten steel material can be supplied.

- For higher temperature applications, fins, tube and casing can be manufactured from alloy steels to allow for dry running at elevated temperatures

- All welded framework and casings are designed rugged to withstand pulsation effects of marine diesel engine.

SPANNER VEG

AFTER MARKET SERVICES

We offer an extensive range of site services and repair work on a twenty four hour, seven day a week basis.

Whether a client requires an urgent spare parts delivery, on site global assistance or simply just support or information on product supply or design issues, our sales and engineering teams are always available.

- Global spare part procurement and delivery.

- Emergency global response teams for all types and makes of boiler.

- Marine repair/installations carried out at yard, anchorage or offshore.

- Minor repairs through to full re-tubing by fully coded welders.

- Marine and land based service and repair of economiser systems.

- Boiler inspections, damage reports, cost estimates, full boiler surveys

- General maintenance, troubleshooting, fault diagnosis and training.

- High pressure water jet washing.

- Boiler chemical cleaning, soda boiling and refractory dry out services.

- Soot blower services.

- NDT Inspection and ultrasonic weld check according to SBG2.

- Internal tube and pipe borescope inspections.